Customer Satisfaction Score is 1. Optimising canned cycles for constant chip thickness. 67 of those who tried HSMWorks (Fusion 360) adopted it (Highest in Class).Minimising NC programming phase lead time whilst fully realising the toolpath intent is a key industry driver, which can be realised through the use of standard features, knowledge management and the automation of the CAM process. Tool definitions, stock, fixture and design geometry from hyperMILL are automatically transferred.

Each products score is calculated with real-time data from verified user reviews, to help you make the best choice between these two options, and. By contrast, hyperMILL rates 4.2/5 stars with 6 reviews. Mastercam rates 4.2/5 stars with 22 reviews. His entire post and the information below was censored / deleted in minutes. based on preference data from user reviews.

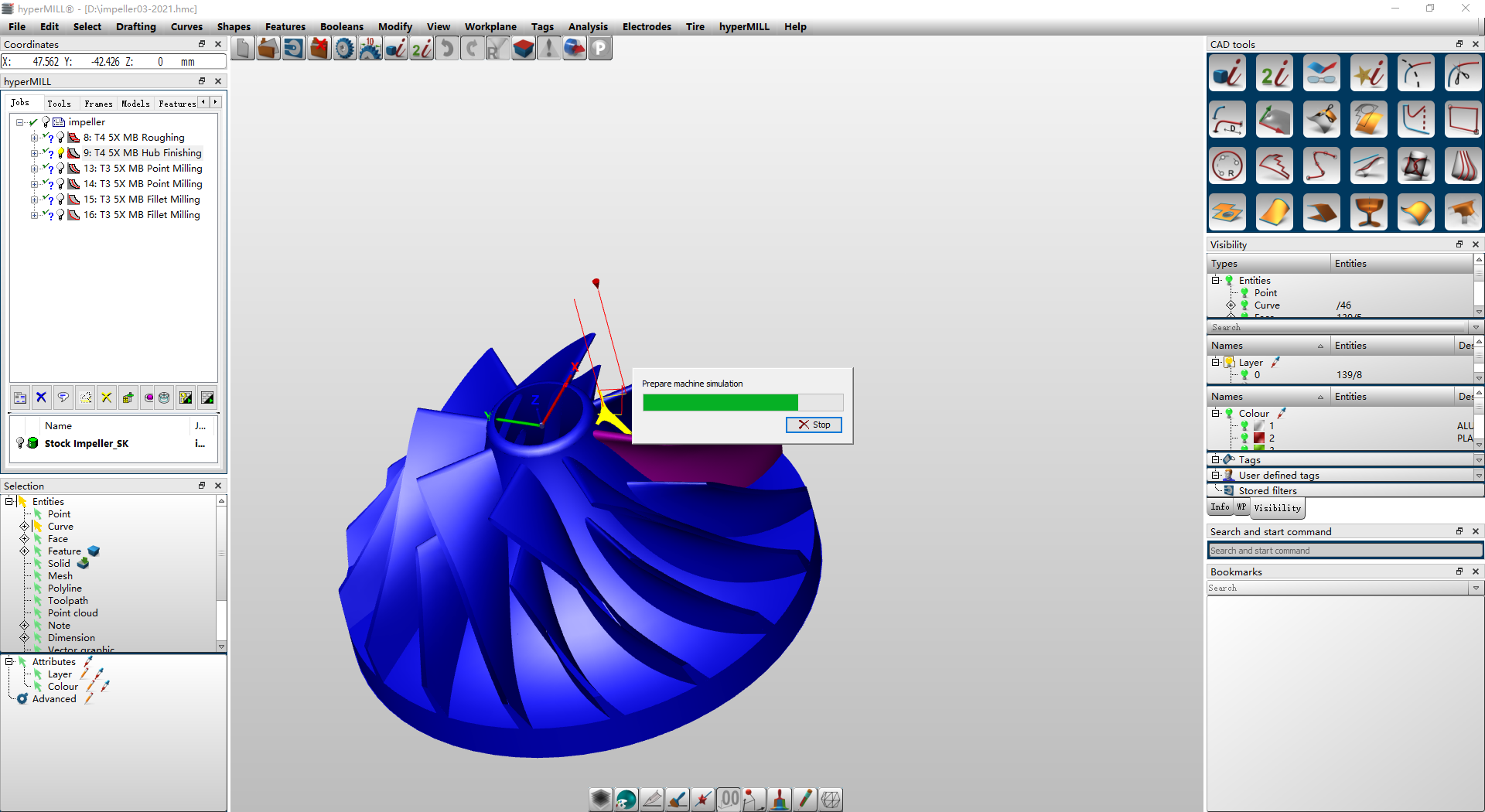

#Nx vs hypermill software

Software that can verify that trajectory of the toolpath will avoid catastrophic machine tool collisions, part gouging or undesired excess material is essential, as is the use of software that can verify that the machining parameters and cutting depths experienced during machining will not subject the cutting tool to excessive or catastrophic force. The hyperMILL Interface launches VERICUT from hyperMILL. Prices for Siemens NX CAM as posted to eMastercam by 'Supernxfan'. CAM provides the toolpaths that will encapsulate the optimal material removal strategies and produces the least expensive, conforming, component for the process in question. Compare price, features, and reviews of the software side-by-side to make the best choice for your business. We process personal data about users of our site, through the use of cookies and other technologies, to deliver our services, personalize advertising, and to analyze site activity.

0 kommentar(er)

0 kommentar(er)